Overview

Ferro alloy refers to various alloys of iron with a highproportion of one or more other elements such as manganese,aluminium, or silicon. They are used in the production ofsteels and alloys.The alloys impart distinctive qualities to steel and cast iron orserve important functions during production. Ferro alloys produced by us are used as raw materialsfor the manufacture of stainless steel products. Wealso sell specialised ferro alloys – low and mediumcarbon – for special steel applications. We sell ferroalloys of various grades, a finished product, to steelcompanies primarily in the states of Odisha,Jharkhand, Karnataka, Uttar Pradesh, Haryana andRajasthan.We also export ferro alloys to South Korea,Indonesia, Thailand, Taiwan, Japan, New Zealand,United Kingdom.We also undertake conversion of manganese ore andchrome ore to silico manganese and ferro chromerespectively for an Indian steel conglomerate on anon-exclusive basis

Features

All the Ferro Alloy being produced by us is through the submerged arc furnace route thus helping us make our products in the most cost efficient way with maintaining quality.

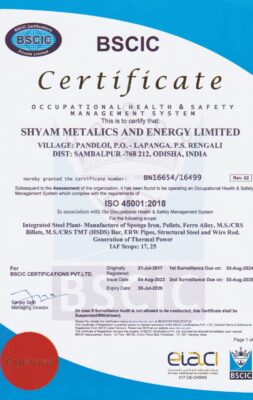

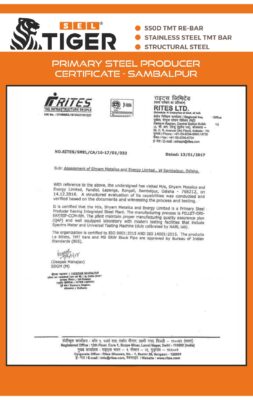

Certificates

It helps in enhancing corrosion resistance and oxidation resistance and aids in high temperature strength. It is primarily used in Stainless Steel industry along with being used as an additive in special steel for construction amongst many others.

| High Carbon Ferro Chrome – Size: 10 – 150MM; 10-100 MM; 25 – 150 MM(HC FeCr) | ||||||||||

| Cr | Si | C | P | S | ||||||

| 57%-63% | 4% Max | 8% Max | 0.40% Max* | 0.05% Max | ||||||

| 57%-63% | 4% Max | 8% Max | 0.020% Max* | 0.05% Max | ||||||

| 57%-63% | 4% Max | 8% Max | 0.15% Max* | 0.05% Max | ||||||

Ferro Silicon acts as a strong steel oxidant. It helps in increasing strength of steel and is in making Stainless steel , ball bearings along with high permeability steel for electric transformers. It is primarily in special steels and used in small quantities in mild steel. Ferro silicon is also used for manufacture of silicon, corrosion-resistant and high-temperature resistant ferrous silicon alloys, and silicon steel for electromotors and transformer cores.

| Ferro Silicon (FeSi) – Size: 10 – 50MM; 25 – 150 MM | ||||||||||

| Si | C | AI | P | S | ||||||

| 70% – 75% | 0.15% Max | 1.5% Max | 0.05% Max | 0.05% Max | ||||||

SiMn is the most preferred alloy for making steel and is used in almost all grades of making steel.Here, manganese is introduced in steel and si is not deleterious along with the additional advantage of low levels of phosphorous and Alliminium in making steel.

| H.C Silico Manganese (Low Phos) – Size: 10/20 – 50/60/70/80 MM; 25 – 150 MM | ||||||||||

| Mn | Si | C | P | S | ||||||

| 65% – 70% Min | 16% – 17% Min | 2.0% Max | 0.25% Max | 0.03% Max | ||||||

| 60% – 65% Min | 14% – 16% Min | 2.0% – 2.5% Max | 0.25% Max | 0.03% Max | ||||||

| 50% Min | 12% Min | 3.0-3.5% Max | 0.30% Max | 0.04% Max | ||||||

| 40% Min | 10% Min | 3.0-3.5% Max | 0.30% Max | 0.04% Max | ||||||

FeMn is mainly used in stainless steel industry followed by the steel industry to make flat steel majorly. It helps in deoxidising and de-sulphurising agent along with adding hardness for wear and tear to steel.

| High Carbon Ferro Manganese (HC FeMn) – Size: 10/20 – 50/60/70/80 MM; 25 – 150 MM | ||||||||||

| Mn | Si | C | P | S | ||||||

| 75% – 80% Min | 1.2% – 1.5% Max | 6% – 8% Max | 0.25% Max | 0.03% Max | ||||||

| 70% – 75% Min | 1.2% – 1.5% Max | 6% – 8% Max | 0.30% Max | 0.03% Max | ||||||

| 65% – 70% Min | 1.2% – 1.5% Max | 6% – 8% Max | 0.30% Max | 0.03% Max | ||||||