Overview

SHYAM SEL & POWER LIMITED – PITHAMPUR UNIT

|

Product

|

Key Features

|

|---|---|

|

Stainless Steel Billets

|

High purity, macro etched, customizable grades

|

|

Wire Rods

|

5.5–32 mm, automated lines, tight tolerances

|

|

Stainless Steel Wires (Industrial & Weld)

|

0.7–16 mm, MIG, TIG, Spring, Nail, Braiding, Redraw

|

|

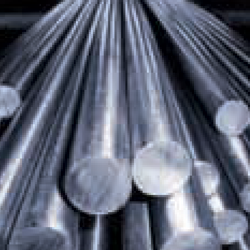

Bright Bars

|

5–100 mm, cold drawn, pump shaft quality

|

|

Hot Rolled Bars

|

20–100 mm, structural & mechanical

|

|

SEL TIGER Stainless Steel Rebars

|

BIS 16651 certified, corrosion-resistant

|

Product Details

STAINLESS STEEL CONTINUOUS CAST BILLETS

Billet Sizes:

- 140 mm x 140 mm → 800–1000 kg

- 160 mm x 160 mm → 1000–1200 kg

Features:

- Automatic mold control

- Macro etch & ultrasonic testing

- Uniform quality for rolling and machining

STAINLESS STEEL WIRE ROD

Technology:

Produced on Danieli Morgårdshammar mills with:

- Level-II automation

- Hot reheating furnace

- 3-pass/9-pass rolling layout

- Coil Weights: 800 – 1200 kg

- Size: 5.5 mm – 32 mm (coils), 5.5 mm – 16 mm (from block)

STAINLESS STEEL BRIGHT BARS

Polished for Precision. Trusted for Performance.

Manufactured through cold drawing, polishing, and buffing, our Bright Bars provide tight dimensional tolerances, superior corrosion resistance, and a flawless finish—ideal for high-end manufacturing and industrial use.

Grades – AISI Designation:

- AISI 201

- AISI 202

- AISI 204Cu

- AISI 301

- AISI 302

- AISI 303

- AISI 304L

- AISI 304

- AISI 316L

- AISI 316

- AISI 304J2

- AISI 304H

- AISI 304LSi

- AISI 308

- AISI 309

- AISI 310

- AISI 310S

- AISI 314

- AISI 317

- AISI 321

- AISI 316Ti

- AISI 347

- AISI 347H

- AISI 430

- AISI 430L

- AISI 434

- AISI 410L

- AISI 410

- AISI 420

- AISI 431 etc.

DIN Designation:

- 1.4372

- 1.4373

- 1.4597

- 1.4310

- 1.4300

- 1.4305

- 1.4306

- 1.4301

- 1.4404

- 1.4401

- 1.4306

- 1.4948

- 1.4306

- 1.4316

- 1.4828

- 1.4845

- 1.4841

- 1.4494

- 1.4541

- 1.4571

- 1.4550

- 1.4961

- 1.4016

- 1.4113

- 1.4006

- 1.4021

- 1.4057

- Duplex Grade: 1.4462

Specifications:

- Size Range: 5 mm – 100 mm

- Length: 2500 mm to 7316 mm (8.2 ft – 24 ft)

- Tolerance Classes: h8, h9, h10, h11, f8, e8, k10, k12

Supply Conditions:

Cold Drawn Polished, Peeled & Polished, Centreless Ground, Annealed, Buffed (Mirror Finish), QT 700 / 800 / 850 / 900, PSQ – Pump Shaft Quality, Hardened & Tempered.

Applications:

- Automotive shafts, fasteners

- Engineering machinery

- Textile and food-grade equipment

- Construction & infrastructure fittings

Testing & Quality Assurance:

- Chemical Analysis: Optical emission spectrometry, wet analysis

- Mechanical Testing: Tensile, torsion, bend, wrap, hardness

- NDT: Ultrasonic, Magnetic Particle, Liquid Penetration

- Corrosion Testing: IGC, Macro Etch

- Compliances: BIS, ISO 9001, ISO 14001, REACH, RoHS, CBAM-ready

- All processes are backed by Level-II automation for consistent product precision and data-driven quality tracking.

STAINLESS STEEL HOT ROLLED BARS

Built for Strength. Designed for Versatility.

Our round bars are rolled from high-quality billets and undergo advanced processing for enhanced strength, durability, and corrosion resistance. With exact size tolerances, they are perfect for demanding structural and mechanical use cases.

Available Sizes:

- Diameter: 20 mm – 100 mm

- Tolerance: IS / ASTM / DIN / EN

- Bundle Weight: 1000 – 1200 kg

- Supply Conditions: Hot Rolled, Pickled

Grades – AISI Designation:

(Same as listed in Bright Bars section)

DIN Designation:

(Same as listed in Bright Bars section)

Applications:

- Structural components

- Precision-machined shafts

- Industrial tools

- Decorative steel applications

STAINLESS STEEL WELDING WIRES

2.1 GTAW (TIG)

- Size: 0.8 – 4.0 mm

- Packaging: Plastic tubes in corrugated or wooden boxes

- Cut Lengths: 350 – 2000 mm

- Surface: Bright

- Customization: Heat number, brand name, batch marking

- Application: Critical welding of stainless/dis-similar steels

2.2 GMAW (MIG)

- Size: 0.838 – 1.143 mm

- Surface: Bright, Matte, Semi Bright

- Application: Automated/semi-automated welding for fabrication

2.3 SAW – Submerged Arc

- Size: 1.6 – 4.0 mm

- Surface: Bright/soap-drawn matte

- Packaging: Wooden pallets

- Application: High-deposition welding in heavy fabrications

2.4 MMAW – Manual Arc Welding

- Size: 1.6 – 4.0 mm

- Packaging: 300 mm rods, 5–7 kg boxes or 20+ kg cartons

- Application: Ideal for maintenance, harsh conditions

Testing Facilities:

- Tensile, bend, wrap, torsion, hardness testing (Rockwell & Brinell)

- Microscopic analysis, IGC testing

- Spectrochemical analysis

- Cold upsetting & radioactive contamination

STAINLESS STEEL WIRES

Types & Range:

- Medium/Thick Wire: 0.70 – 15.00 mm

- Welding Wire: 0.800 – 1.60 mm

- Core Wire: 2.00 – 5.00 mm

- Cold Heading Wire: 2.00 – 15.00 mm

- Electro Polish Wire: 1.00 – 12.00 mm

- Spring Wire: 0.70 – 10.00 mm

- Rope Wire, Redraw Wire, Nail Wire, etc.

Types & Range:

MS Carrier, Spools, Layered Coils, Wooden Boxes, Euro Coil

Product Range

| Size Range (mm) | 120 x 120, 140x 140, 160 x 160, 180 x 180 & 200 x 200 |

| Size Tolerance | + 3mm for sizes upto 140mm & +6/-3mm for sizes above 140mm |

| Length (meter) | 6 meters and above with tolerance for fixed length supply + 50mm, – 0.00mm |

| Grades (illustrative) | 1. Stainless Steel – Austenitic Grades: 201,202, AML- 7, AML- 6, AML- 5 – Austenitic Grades: 302,304,304H, 304L,316,316L, 310,321 other welding grades – Ferretic Grades: 410,420,431,409,409L, 430 – Duplex(Austenitic – Ferretic): ASTM S 32101, S 32304, S 32205, S 31803, S 32507

2. Auto Steel Grades – 20Mn Cr 5;16Mn Cr5, SAE 4140, 8620, 8622, SAE 4140 3. Bearing Steel – SAE 52100, EN 31, EN 31 (M) 4. Spring Steel – EN 45, E 45 A, EN 47, EN 48, EN 48 A, 50 Cr V M04 5. Carbon Steel – EN 15 B, EN 32 B,EN 9, SAE 1030, EN 43 C, EN 43 B, EN 8,SAE 1541, EN 8 A, EN 8C, EN 8D, EN 18, EN 18C, EN 18 D, E 19, E19C, 16Mn Cr 5, SAE 8620, SAE 8622 6. Cold Heading Quality Steel – AISI 1006 to AISI 1018, AISI 10B36, AISI 15 B25, AISI 15 B41, AISI 10 B21M, SCM 415 H, SCM 435, AISI 4135, EN 24, AISI 1541 |

| Size Range (mm) | Thickness – 6mm to 25mm |

| Diameter | Width – 200mm |

| Size Tolerance | + 2% |

| Length (meter) | 6 meters with + 2% Tolerance |

| Grades | Austenitic Grades: 200 & 300 Series |

| Packing | Standard or as mutually agreed with the customer |

| Size Range (mm) Diameter | 5.5mm to 16mm |

| Size Tolerance | According to IS-1S52/ 19S5 or with close tolerance as mutually agreed with customer |

| Grades | 1. Stainless Steel – Austenitic Grades: 201,202, AML- 7, AML- 6, AML- 5

2. Auto Steel Grades- 20Mn Cr 5;16Mn Cr5, SAE 4140, S620, S622, SAE 4140 |

| ID/OD of coil (meter) | 1200 OD, ID – 900 Height 1500 mm |

| Weight of Coil (kg) | About 1200 kgs |

| Packing | Compacted coil with Four Straps |

| Size Range (mm) Diameter | 5.5mm to 16mm |

| Size Tolerance | According to IS-1S52/ 19S5 or with close tolerance as mutually agreed with customer |

| Grades | 1. Stainless Steel – Austenitic Grades: 201,202, AML- 7, AML- 6,AML- 5

2. Auto Steel Grades- 20Mn Cr 5;16Mn Cr5, SAE 4140, 8620, 8622, SAE 4140 |

| ID/OD of coil (meter) | 1200 OD, ID – 900 Height 1500 mm |

| Weight of Coil (kg) | About 1200 kgs |

| Packing | Compacted coil with Four Straps |

| Size Range (mm) Diameter | 20 x 20 x 3 to 5mm; 25 x 25 x 3 to 6mm;30 x 30 x 3 to 6mm, 35 x 35 x 3 to 6mm |

| Size Tolerance | According to IS-1825/1985 or Close tolerance can be supplied by mutual agreement |

| Length (meter) | 6 Meters |

| Grades | Stainless Steel Grades: 201, 304 Duplex Stainless Steel Grades |

| Packing | Standard or as mutually agreed with customer |

| Size Range (mm) Diameter | 8 – 12mm (in coils) & Above 12 – 32mm (Straight Length) | |

| Size Tolerance | According to ASTM A615 | |

| Grades | Stainless Steel Grades: 304L, 316L Duplex Steel: ASTM S32 101;S32 205; S31 803 |

|

| Weight of Bundle

|

2 MT Max for straight length and about 1200 kgs in coils | |

| S 32 101 | S 32 205 | |

| Mechanical Properties (for each grade)

|

Yield Strength (MPa Min) | |

| > 500 | > 600 | |

| Ultimate Tensile Strength (MPa Min) | ||

| > 500 | > 750 | |

| Elongation (%) | ||

| 30 | 35 | |

| Size Range (mm) Diameter | Above 25mm and upto 70mm |

| Size Tolerance | According to IS-1852/ 1985 or with close tolerance as mutually agreed with customer |

| Length (meter) | From 6 to 9 |

| Grades | 1. Stainless Steel – Austenitic Grades: 201,202, AML- 7, AML- 6, AML- 5

2. Auto Steel Grades- 20Mn Cr 5;16Mn Cr5, SAE 4140, S620, S622, SAE 4140 3. Bearing Steel – SAE 52100, EN 31, EN 31 (M) |

| Weight of Bundle | 2 MT Max |

| Packing | Standard or as mutually agreed with customer |

| Size Range (mm) Diameter | 8 – 12mm (in coils) & Above 12 – 32mm (Straight Length) | |

| Tolerance on length and Nominal Mass Grades | According to IS 1786 – 2008 for coil batch tolerance – not applicable Fe 500 & 550 | |

| Grades | Stainless Steel Grades: 304L, 316L Duplex Steel: ASTM S32 101;S32 205; S31 803 |

|

| Weight of Bundle

|

Tolerance on length and Nominal Mass Grades | |

| Standard Fe 500 | Standard Fe 500 | |

| Mechanical Properties (for each grade)

|

Yield Strength (MPa Min) | |

| 500 | 550 | |

| Ultimate Tensile Strength (MPa Min) | ||

| 545 | 585 | |

| Elongation (%) | ||

| 14.5 | 10 | |